“Old Guy Street Smart” Plastics Consulting

Time and again the proven way to cover ALL aspects of materials and design is to have a conversation with someone who knows what questions to ask.

Develop Application

“Google” and AI are often the tools used for gathering information, but seldom do these inquiries generate sufficient information about these materials’ properties and, more importantly, their limitations.

Training

The world of engineering plastics and composites has changed rapidly over the years. Many companies’ engineers and other specifiers don’t have the “functional experience” to properly investigate, review, choose and design in this material space.

Consulting

Experienced consultants typically get to see many more industries, organizational cultures, technologies and ways of working due to the nature of our work. This can be beneficial and helpful, so your organization does not need to fumble through the learning curve associated with doing something for the first time.

In my 47+ years in the engineering plastics, composites. and powder coatings markets, I’ve seen applications from HDPE hose spacers to high-performance materials for medical, semiconductor and even satellite applications, and everything in-between. I have seen what works and what usually does not work. That’s “STREET SMART” experience you cannot easily get anywhere else.

Testimonials

General FAQs

What are the reasons for a company to hire an external consultancy firm instead of using its own internal staff?

The world of engineering plastics and composites has changed rapidly over the years. Many companies’ engineers and other specifiers don’t have the “functional experience” to properly investigate, review, choose and design in this material space.

In general, these are the reasons you might hire a consultant:

- Provides specific expertise for your project

- Boosts your capacity

- Broadens the skills and knowledge you have available

- Makes you more agile

- Helps you generate new ideas

- Reduces your time to market

What are Engineering or Industrial Plastics - Composites?

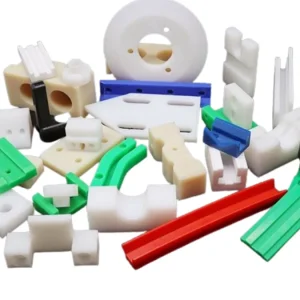

Unlike the “plastics” you typically see and use (water bottles, food containers, cups, etc), industrial plastics are very robust materials used in industrial components, typically process and lifting machinery. Primarily used as wear components (bearings, bushings, wear pads) they have become the preferred material family for many such applications due to their improved wear resistance, reduced dependency on external lubrication, corrosion resistance and lighter weight.

What criteria are used to select the best materials?

In most cases, there isn’t just one specific “perfect” material for a given application. Depending on the application requirements, several materials could be viable candidates, each with their own product and performance profiles. The application development process is designed to find the material with the best combination of properties for that specific component. NOTE: price and size availability are inherent properties, not all materials are available in all shapes and sizes, and some are quite expensive.